Research Area

6.3 Display technologies

■Flexible OLED displays with longer lifetime and higher color purity

Organic light-emitting diode (OLED) devices use active materials such as alkali metals for their electron injection layer. Since these materials are sensitive to moisture and oxygen, the devices deteriorate over time when used on a film substrate in air. This poses the greatest challenge in putting a flexible OLED display to practical use. To address this issue, we are researching and developing an OLED that does not use alkali metals and can better withstand oxygen and moisture, called an inverted OLED. In FY 2018, we worked to identify the principle of materials and formation process for an inverted OLED with higher performance.

To achieve an inverted OLED with a lower voltage, higher efficiency and a longer lifetime, the selection of electron injection materials is significantly important. The results of consideration of various materials demonstrated that a special organic material containing boron is suitable for improving the electron injection performance and lifetime because of factors such as electron orbit energy. We also found that an inverted OLED with a lower voltage and longer lifetime can be achieved when using solution deposition for the formation process of an electron injection layer, rather than vacuum deposition. We examined the reason for this from the results of elementary analysis and found that a small amount of zinc oxide in the lower layer dissolved during the solution deposition process of the electron injection layer, changing the energy levels of impurities formed in the electron injection layer and thus contributing largely to the improvement of device performance(1). On the basis of these results, we demonstrated that an inverted OLED with a solution-processed electron injection layer causes no luminescent degradation even when using a film with low gas-barrier properties, achieves a lifetime in excess of 3,000 hours for red and 1,500 hours for green even when it is continuously on, and shows much higher atmospheric stability than usual OLEDs, which cause significant luminance degradation(2).

To reproduce a wide color range of SHV, it is necessary to develop a power-saving and long-lasting OLED with a high color purity. We previously demonstrated that an OLED with a high color purity can be achieved by using a platinum complex having a rigid network molecular structure as the luminescent emitter. A platinum complex is capable of high-color-purity luminescence when used as a single material, but the color purity declines when it is mixed with a host material, which transmits electric energy in the light-emitting layer. To address this problem, in FY 2018, we systematically investigated what kind of host materials are suited for a display with high color purity. The results showed that color purity is deteriorated by unnecessary luminescence generated on the long wavelength side when a part called triazine contained in a host material and a platinum complex, which is a luminescent emitter, approach and interact with each other(3). On the basis of this knowledge, we plan to design a new host material and utilize it for the development of a wide-color-gamut OLED display.

■Technologies for increasing image quality and lowering driving power consumption of large OLED displays

We progressed with our R&D on thin-film transistors (TFTs), which are driving elements of pixels, to increase the image quality and lower the power consumption of sheet-type displays. In FY 2018, we developed a high-mobility TFT that uses zinc oxynitride (ZnON) as the semiconductor material. We found that doping ZnON with a minute amount of impurities improves the electrical characteristics of ZnON-TFT significantly. More specifically, we demonstrated that the switching characteristics of TFTs are improved by adding an element having a large binding energy with nitrogen (such as Ta) and that the mobility is improved by adding an element that contributes to high conductivity (such as In). A ZnON-TFT doped with In achieved a high mobility of 59 cm2/Vs at the maximum.

As a video signal processing technology for increasing image quality, we studied a luminance control method for HDR video. We previously devised a method for controlling the driving power while maintaining the tone representation of light and dark regions when displaying HDR video with a high average luminance. However, since this method controls only light regions, image degradation occurs in intermediate gradations, which has posed a challenge. To address this problem, we devised a method for preventing image degradation by controlling luminance using an optimum signal processing for HDR video and demonstrated its effectiveness with evaluation images(4).

■ Solution-processed devices for large flexible displays

With the goal of realizing a large flexible display that is thin, lightweight and rollable, we are conducting R&D on oxide TFTs that can be fabricated by solution process without using a large vacuum chamber and on light-emitting diodes using semiconductor nanocrystals (quantum dots (QDs)) called QD-LEDs.

Solution-processed oxide TFTs had the problem of low mobility due to many impurities and defects contained in the semiconductor film formed by the solution method. We therefore improved the film quality of semiconductor by using hydrogen injection and oxidation (HIO) process as well as doping the oxide semiconductor (In-Zn-O) with fluorine. This enabled a TFT fabricated by a low-temperature (300ºC) process that can be applied to film substrates to achieve a high mobility (12.8 cm2/Vs) comparable to that of a TFT fabricated by the conventional vacuum process(5).

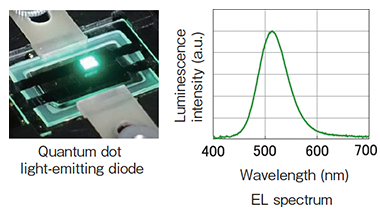

QD-LEDs can control the wavelength and full width at half maximum of the emission spectrum by grain size control of QDs. In FY 2018, we prototyped a QD-LED that uses an indium phosphide material (ZnInGaP/ZnS) as low toxic QDs. We introduced a hole transport layer that can inject holes into the light-emitting layer efficiently while blocking electrons to a QD-LED using ZnInGaP/ZnS QDs that emit green light. This achieved an external quantum efficiency of 3.4% (Figure 6-9)(6). The research on the QD-LED using ZnInGaP/ZnS was conducted in cooperation with ULVAC, Inc.

Figure 6-9. ZnInGaP/ZnS QD-LED and EL spectrum

| [References] | |

| (1) | H. Fukagawa, T. Sasaki, T. Tsuzuki, Y. Nakajima, T. Takei, G. Motomura, M. Hasegawa, K.Morii, and T. Shimizu: "Long-Lived Flexible Displays Employing Efficient and Stable Inverted Organic Light-Emitting Diodes," Advanced Materials, DOI: 10.1002/adma.201706768 (2018) |

| (2) | T. Sasaki, H. Fukagawa, K. Kuwada, M. Hasegawa, K. Morii, T. Shimizu: "Demonstration of Long-Term Stable Emission from Inverted OLED with Imperfect Encapsulation," SID Digest, pp. 811-814 (2018) |

| (3) | Y. Iwasaki, H. Fukagawa, T. Shimizu: "Host Materials Suitable for Organic Light-Emitting Diodes with High Color Purity," ITE Winter Annual Convention, 21D-2(2018). |

| (4) | T. Okada, T. Usui and Y. Fujisaki: "Picture-level Control for Managing HDR Images and Power Consumption for Large OLED Displays," IDW'18 VHF1-2, pp.937-940 (2018) |

| (5) | M. Miyakawa, M. Nakata, H. Tsuji and Y. Fujisaki: "High-performance solution-processed thin-film transistors using fluorine-doped aqueous metal oxides," The 25th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD'18), 3-2 (2018) |

| (6) | K. Ogura, G. Motomura, T. Tsuzuki, Y. Fujisaki, J. Nagakubo, M. Hirakawa and T. Nishihashi: "Efficient Green Light-Emitting Diodes Using ZnInGaP/ZnS Nanocrystals as Cadmium-Free Quantum Dots," Materials Research Society (MRS) Fall Meeting, EP04.10.17 (2018) |